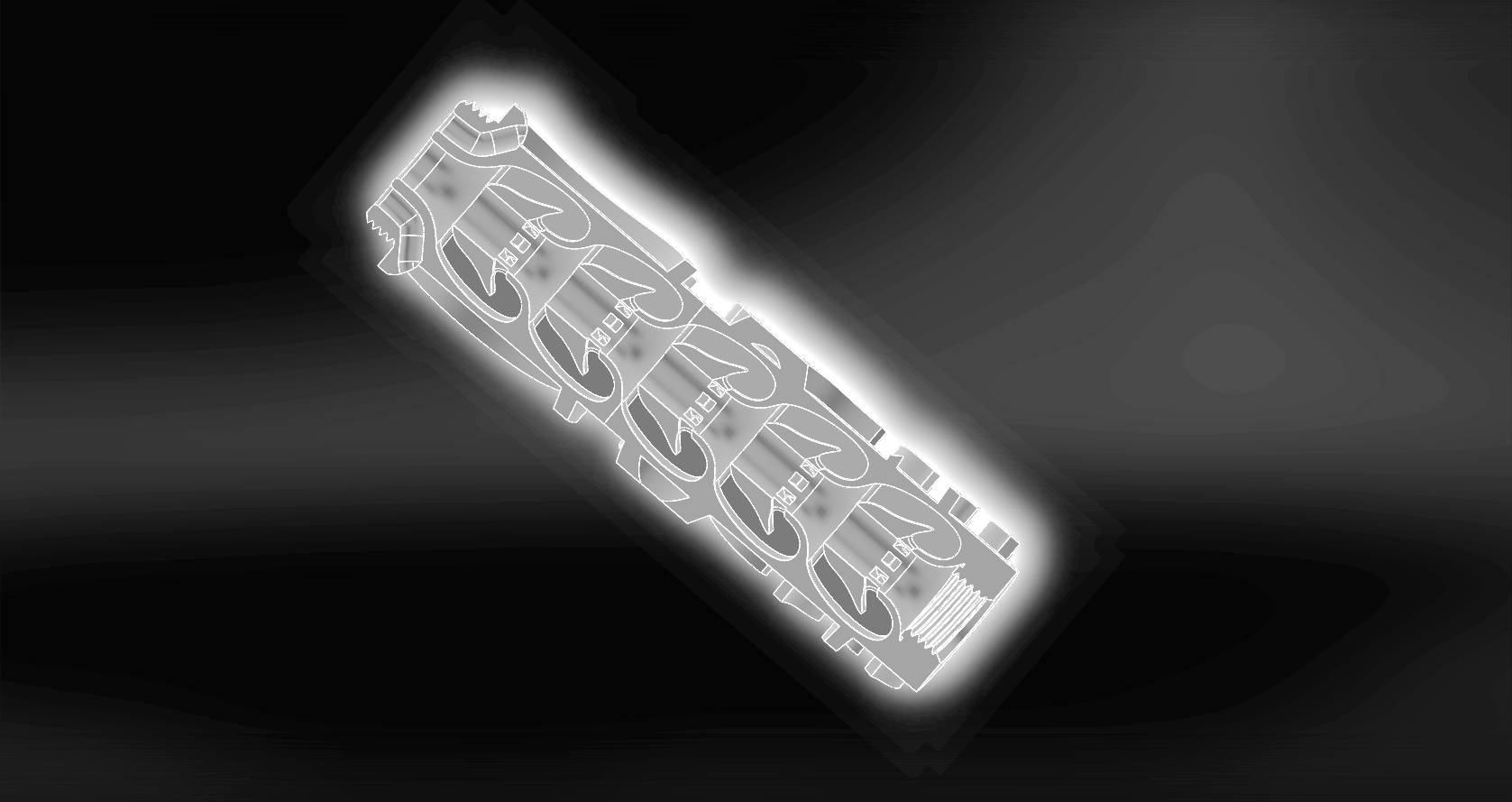

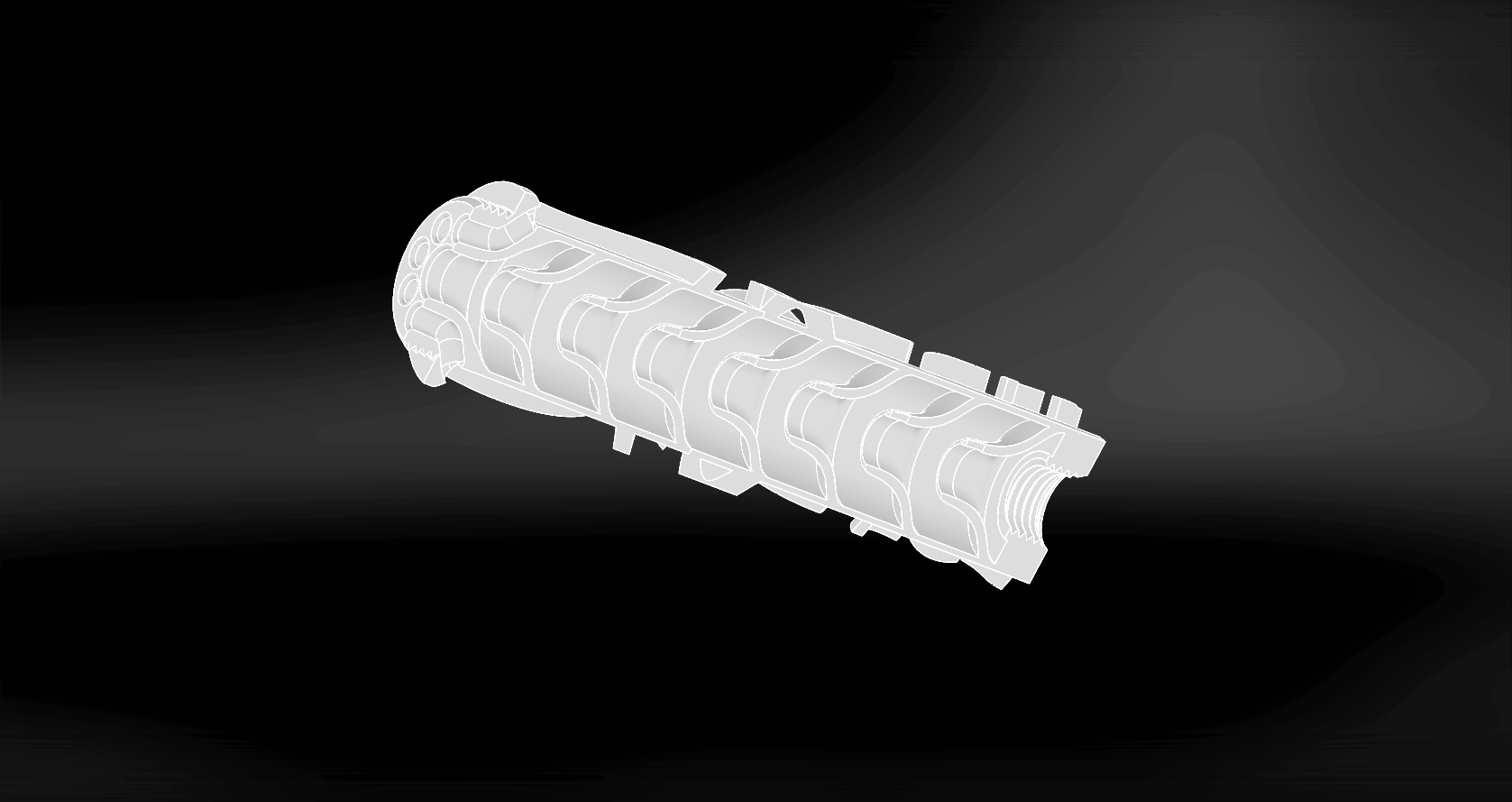

Put simply, the concept here is that the central core aerodynamically restricts flow to muffle the initial blast while the outer core allows flow as freely as possible while disrupting the pressure front responsible for the sound…… at least in theory, in practice things can be somewhat different.

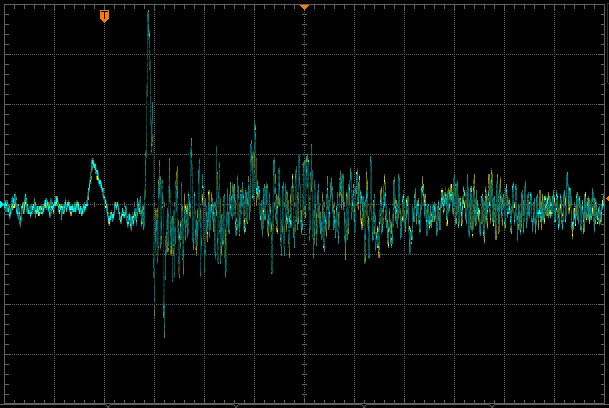

Here is the pickle: theory is where you understand things, but nothing works. Practice is where some things work, but you don’t understand why. I have a habit of combining theory and practice, where nothing works and I have no idea why. A hallmark of good science is a control, in essence a way to know if your hypothesis is valid or not. Instead of simply one control though, for optimum scienticiousness, I want three. I’ll then call up another buddy from STO to dig out the old impulse sound meter, an exotic device unlike conventional sound meters in that it measures peaks from short pressure waves rather than continuous sound, and test all four configurations. Speaking of which, all four configurations are as follows:

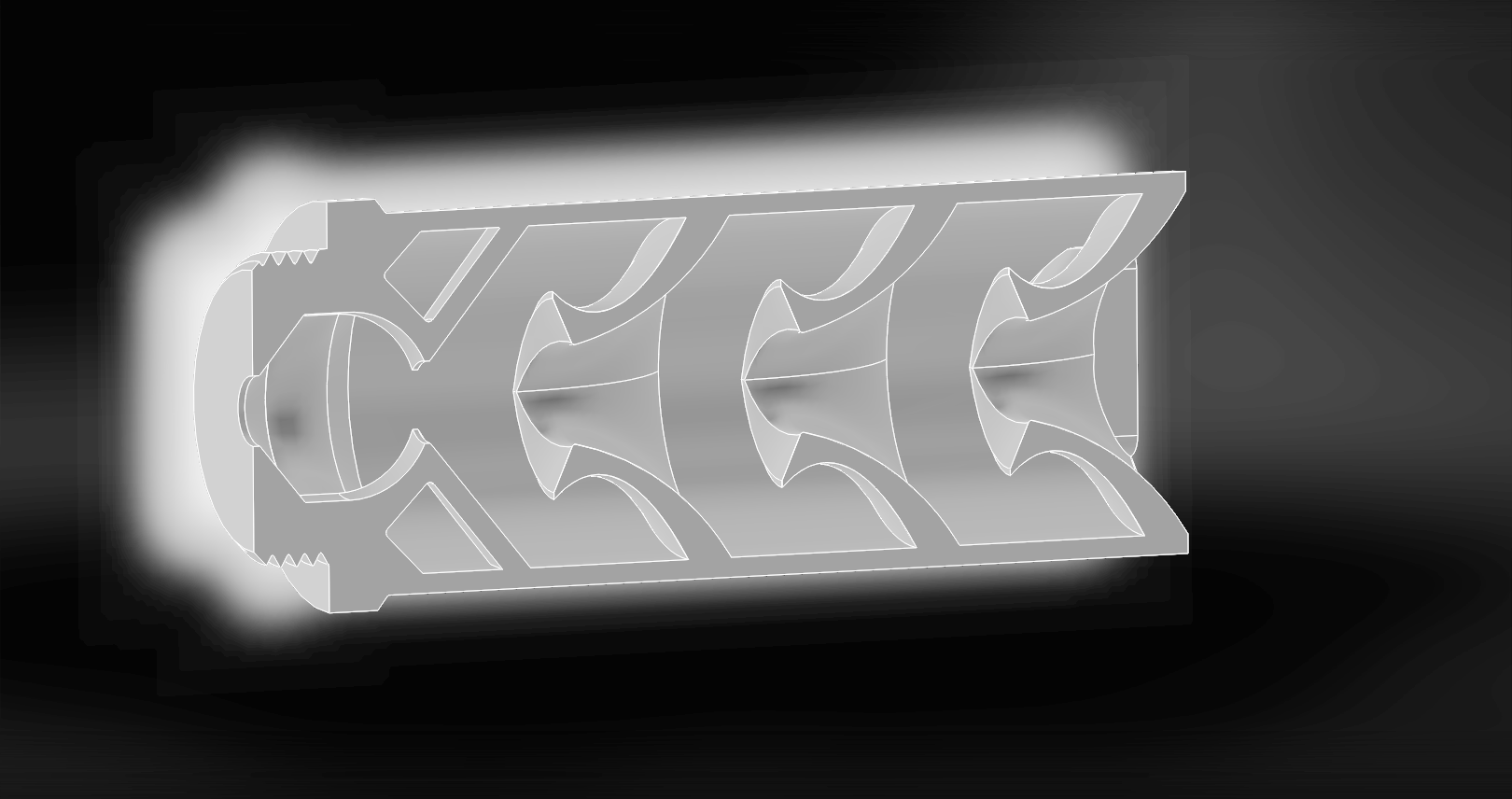

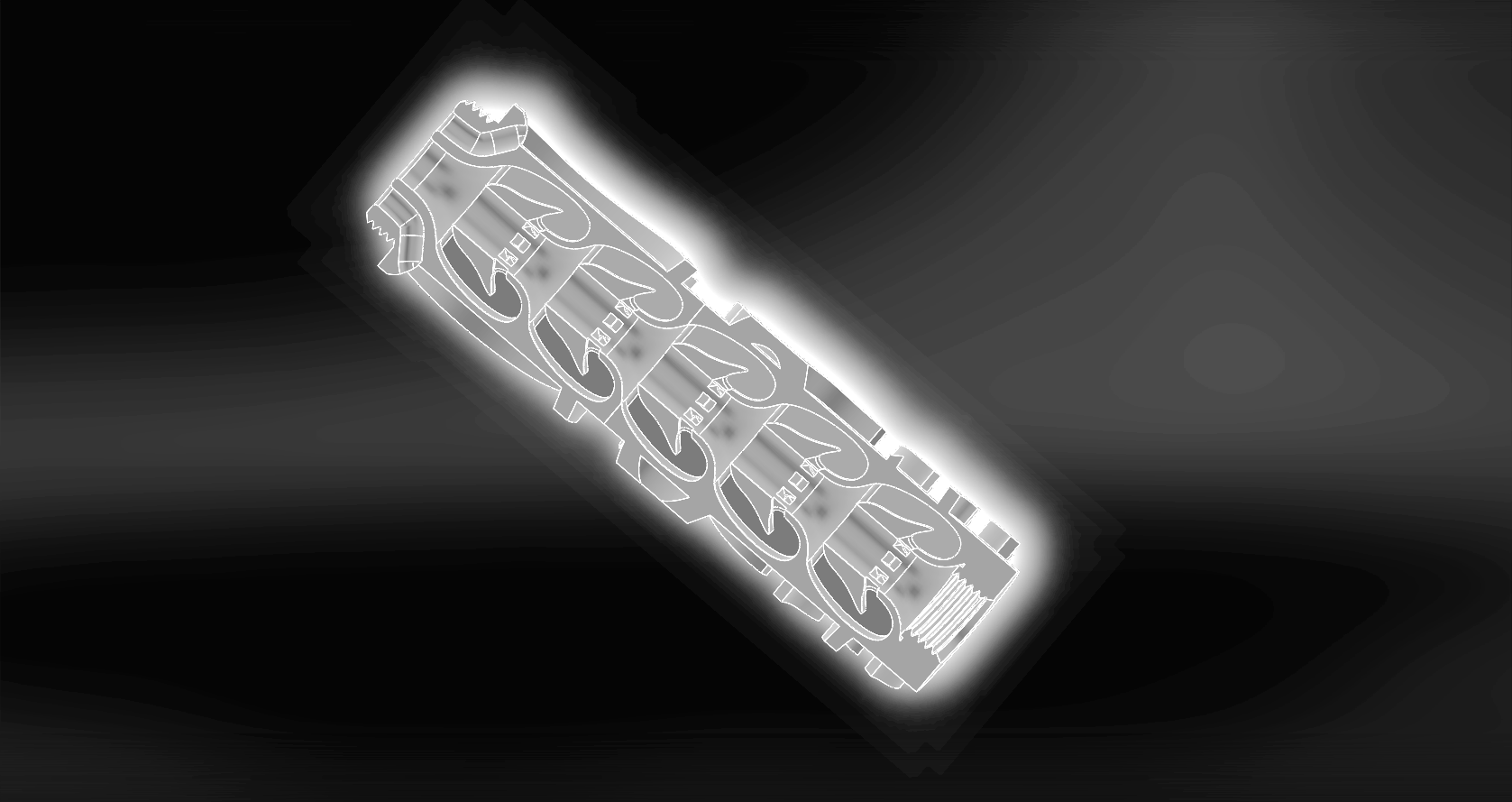

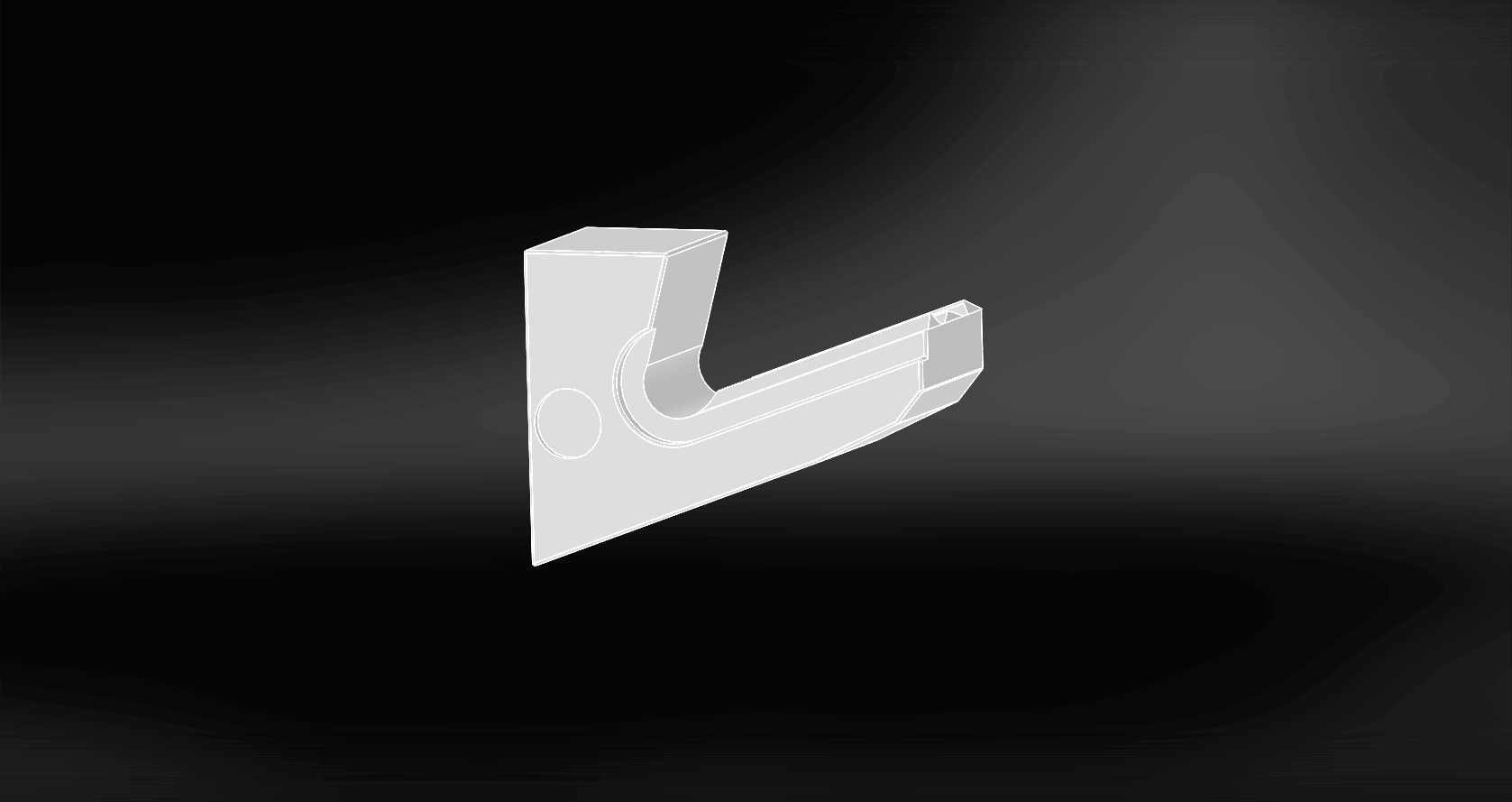

1) Very common in the firearms industry at the moment, even among some of the best brands, is the clipped conical baffle. This design has some, but not excessive, cross-jetting to disrupt forward flow. This design is also widely applied to both supersonic and subsonic suppressor designs, making it arguably applicable here. You might at this point be wondering why I’m not opting for the all too common traditional K-baffle, which is very effective in dealing with subsonic flow moderation. The answer is that the simple K-baffle isn’t that effective at sound moderation, comparatively speaking, although it is very easy to machine which explains part of its prevalence. The more complex and efficient K-baffles are very quiet, but induce a lot of cross-jetting which significantly negatively affect accuracy. They also tend to have tonal issues, so while the results are quiet on the meter they’re also shrill and unpleasant. Some companies, notably Dead Air Armament, have overcome this with much testing and design work but for obvious reasons I’d rather not have to extensively optimize an experimental control, because doing so would rather negate its value as a control as well as detract from the central experiment.

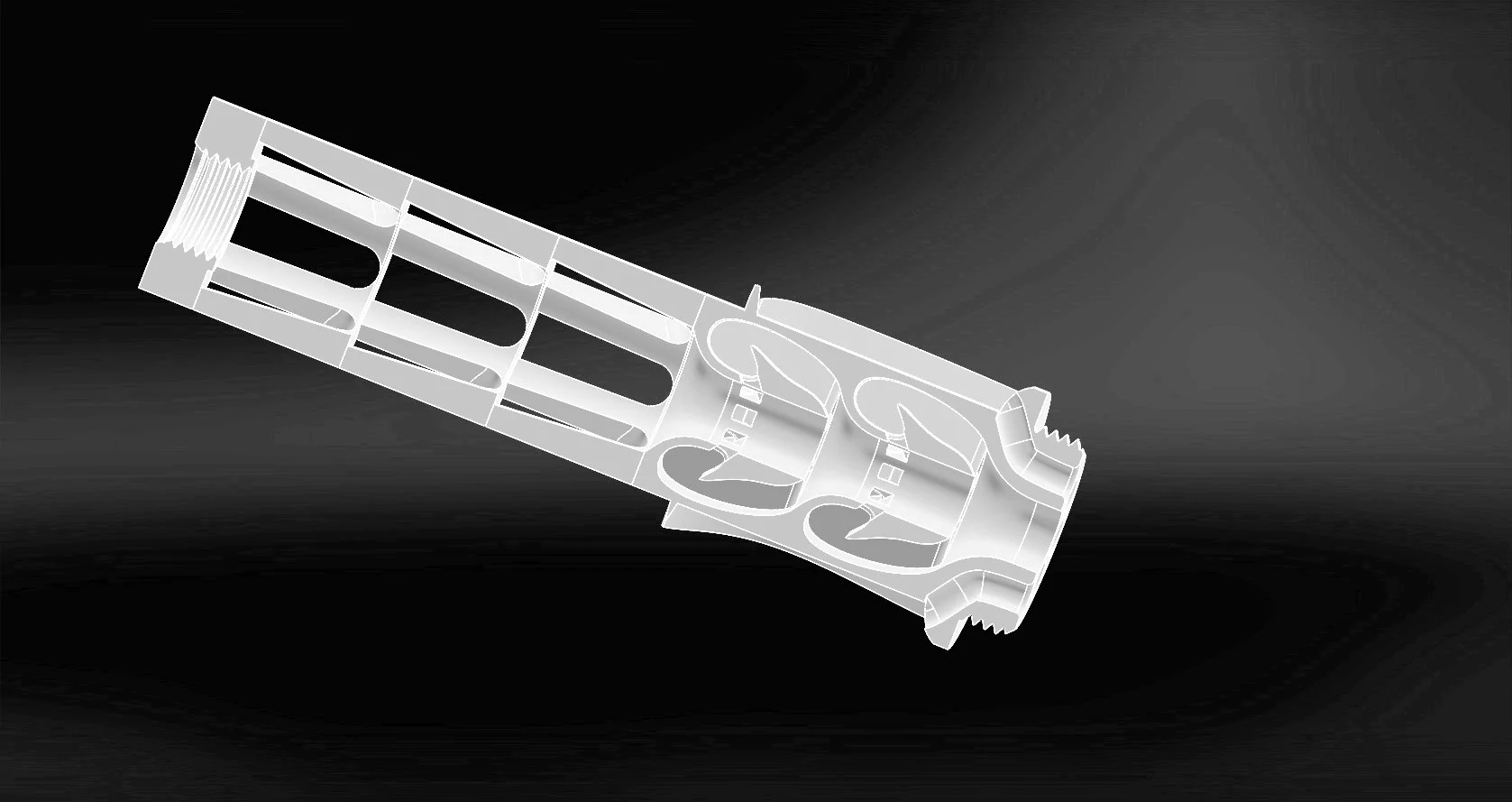

2) What if the clipped conical baffle works better than a Tesla Gas Diode at inhibiting forward flow in a suppressor, but is disadvantaged because it is shoved in a fixed-volume design? A scaled down clipped conical baffle stack used as the center core on the same outer core as the gas diode design would be a worthwhile control.

3) When everyone is doing one thing, and you’re doing something else, maybe that is because you’re a genius but more likely it is because you’re an idiot. I’d be foolish not to make a comparably sized design and pack it with an open-cell material like felt or foam which has worked so well for Huggett and DonnyFL. The architecture is trivial to design, so may as well run with it.

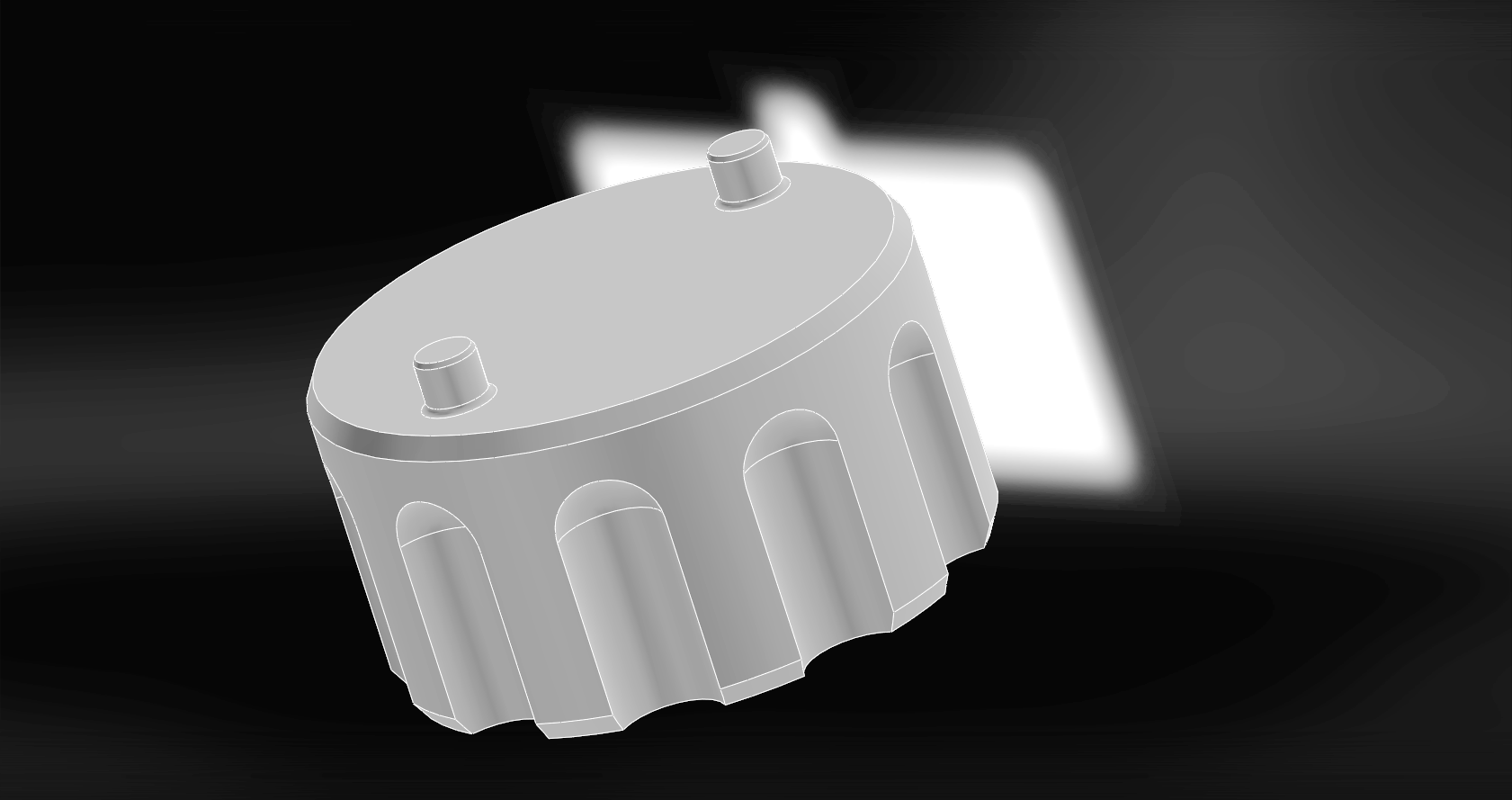

4) And, of course, the entree: my Tesla Gas Diode design. I have no doubt it’ll work, but whether or not it’ll work better than the other designs I have no idea.

And that is where things stand for now. There is a lot of time, design work, and testing between here and there. Also this blog post has dragged on long enough. So I’ll wrap it up here. In part two we’ll dive more into the gritty end of prototyping, a few more subtle elements of design, etc. Then in part 3 we’ll finally get to testing, results, and revisions.