Catch the previous episode HERE.

So first off I want to thank all you crazy people for harassing me to get your hands on, not just a handful of these crazy experimental moderators, but enough of them that you’re actually creating production problems at Silent Thunder Ordnance. When I started I had no idea there was this sort of interest in moderator design and experimentation, it is a pretty fringe nerdy subject , so from all of us to all of you THANK YOU!

If you’ll forgive a little nostalgic reminiscence, I started this whole thing a year and a half ago when I got a brand shiny new FX Crown, which was a lot louder than I wanted, and I foolishly thought I could build a better mousetrap. People started emailing in asking to try one. At first I was just giving them away, the whole thing was just a crazy experiment after all, but that quickly became untenable as they were too expensive and time consuming to produce to just give away in such numbers. So we listed them, secretly, so people could throw a little cash in the hat if they wanted to participate in the experiment. And now this project has outgrown that. It is time to build out something scalable, upgradeable, and with some of the production bells and whistles. It’ll all still be cutting edge and experimental, but key is that it will be modular/upgradeable.

So what does this mean going forward? Well, a couple things. First it means all the carbon moderators are being shelved. All this time I’d been making them by hand, one at a time, which is a surprisingly labor intensive process. It simply wasn’t sustainable.

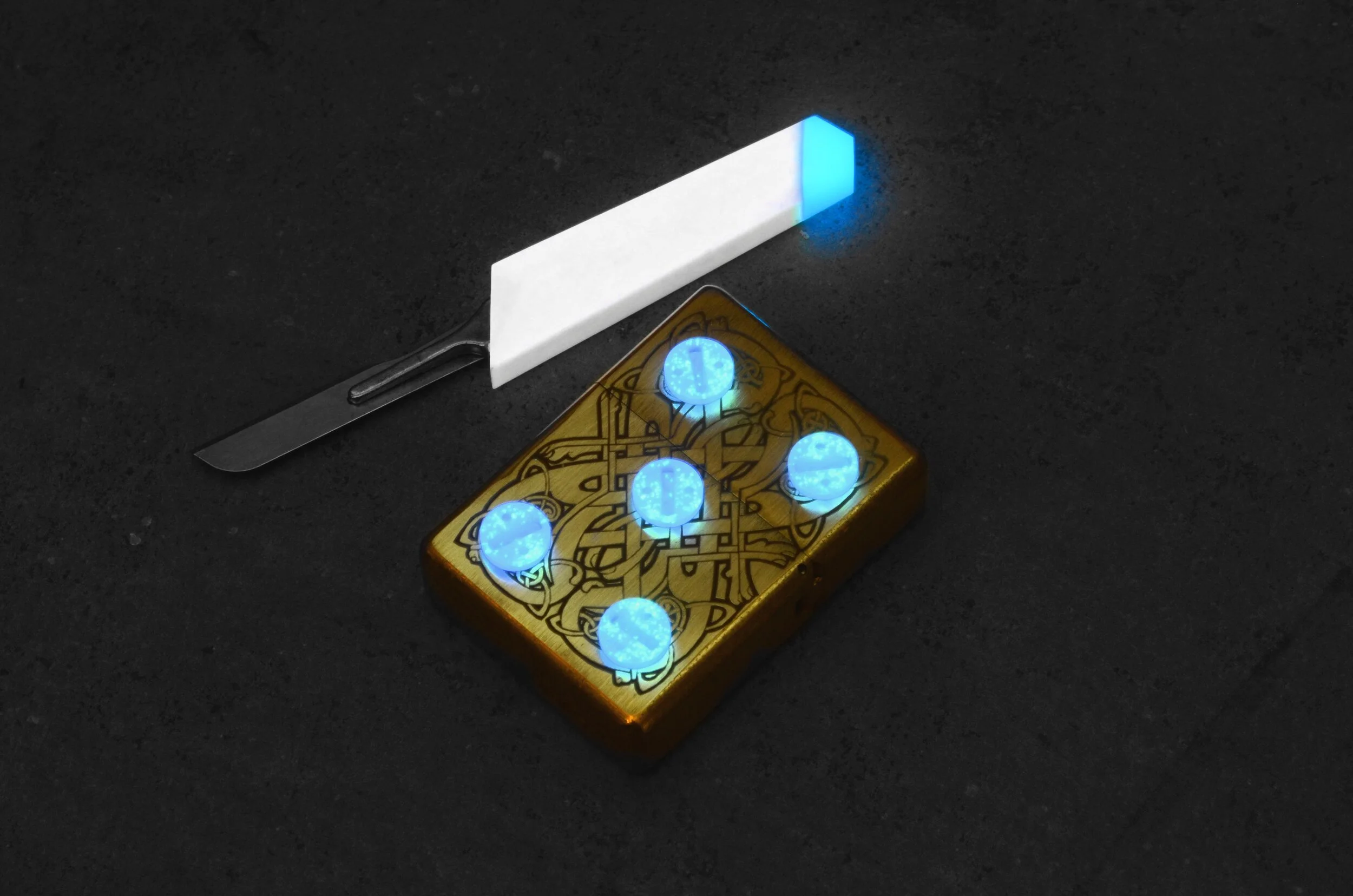

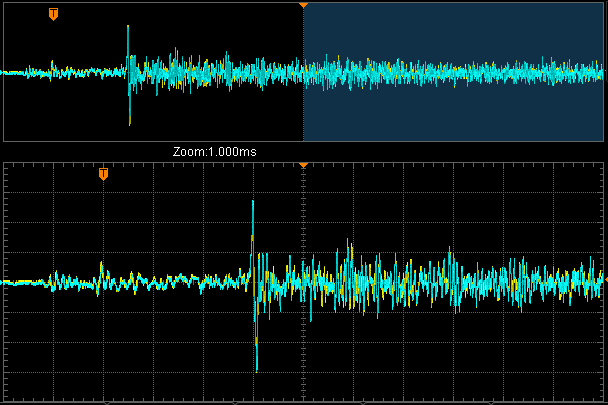

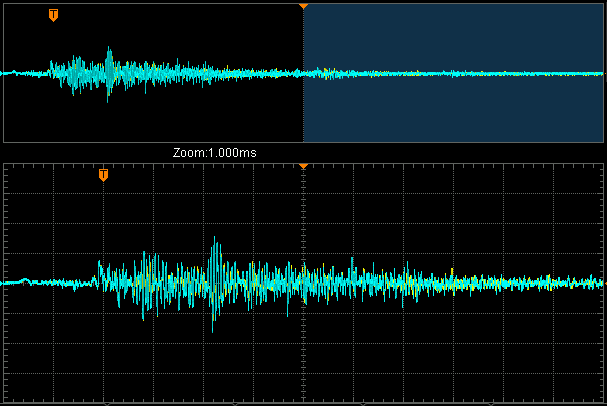

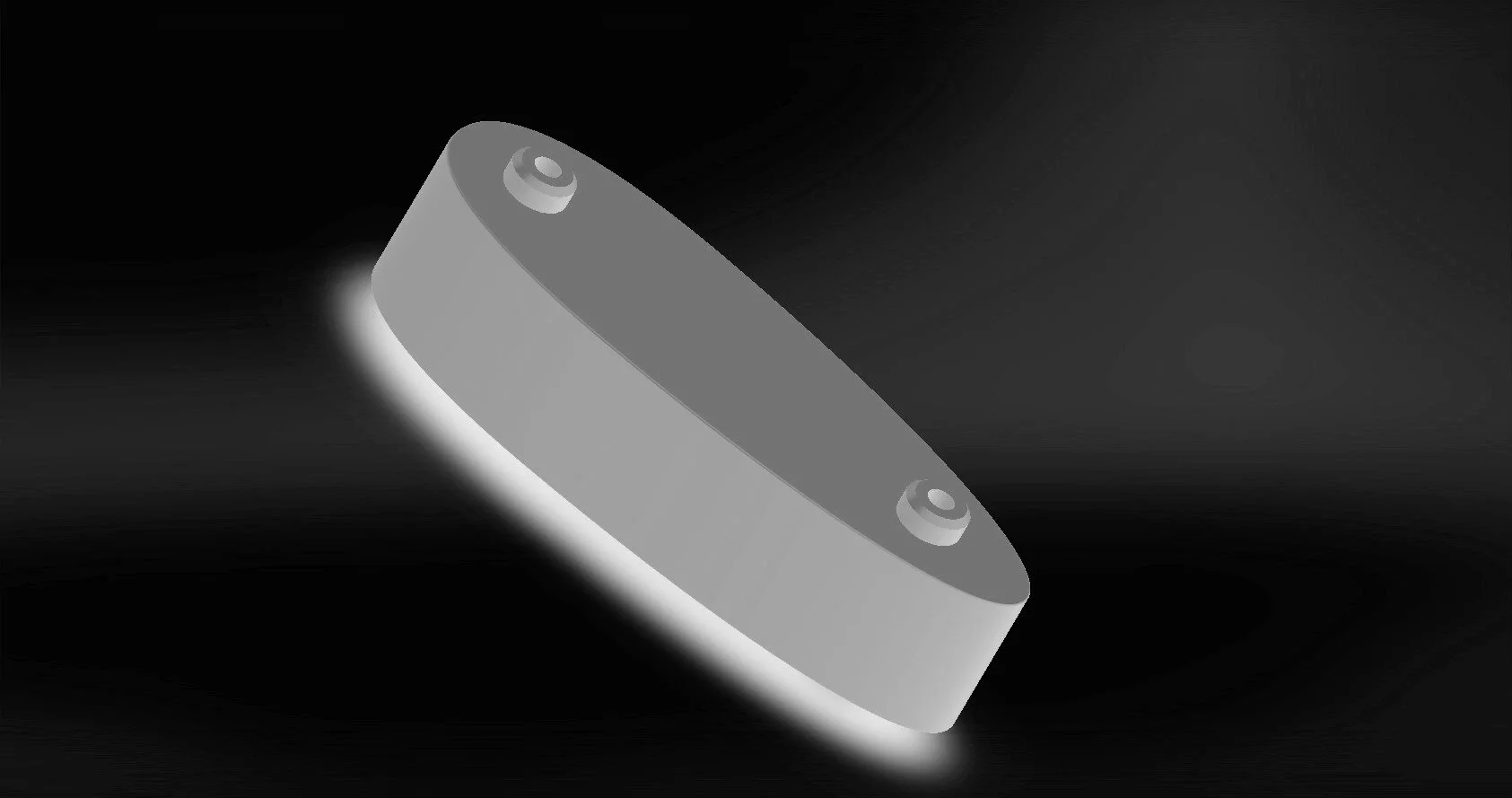

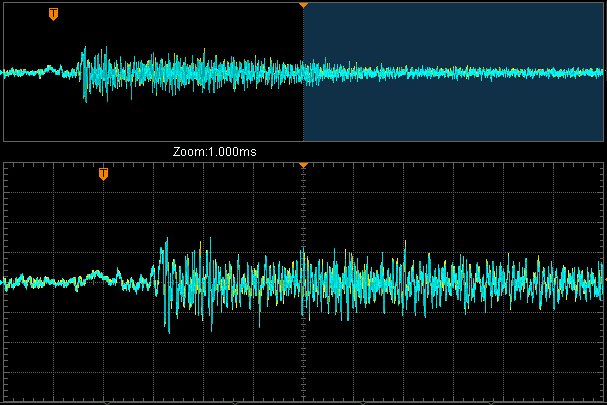

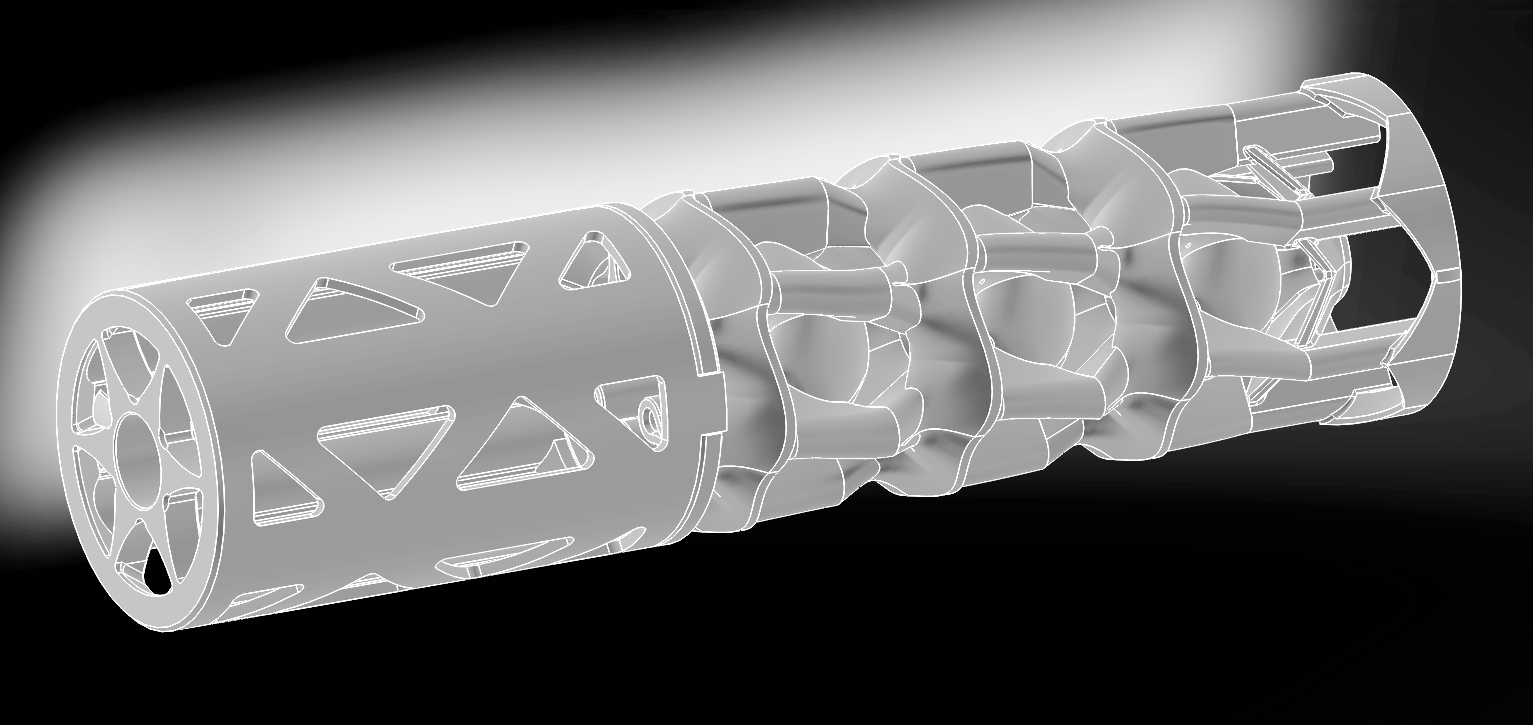

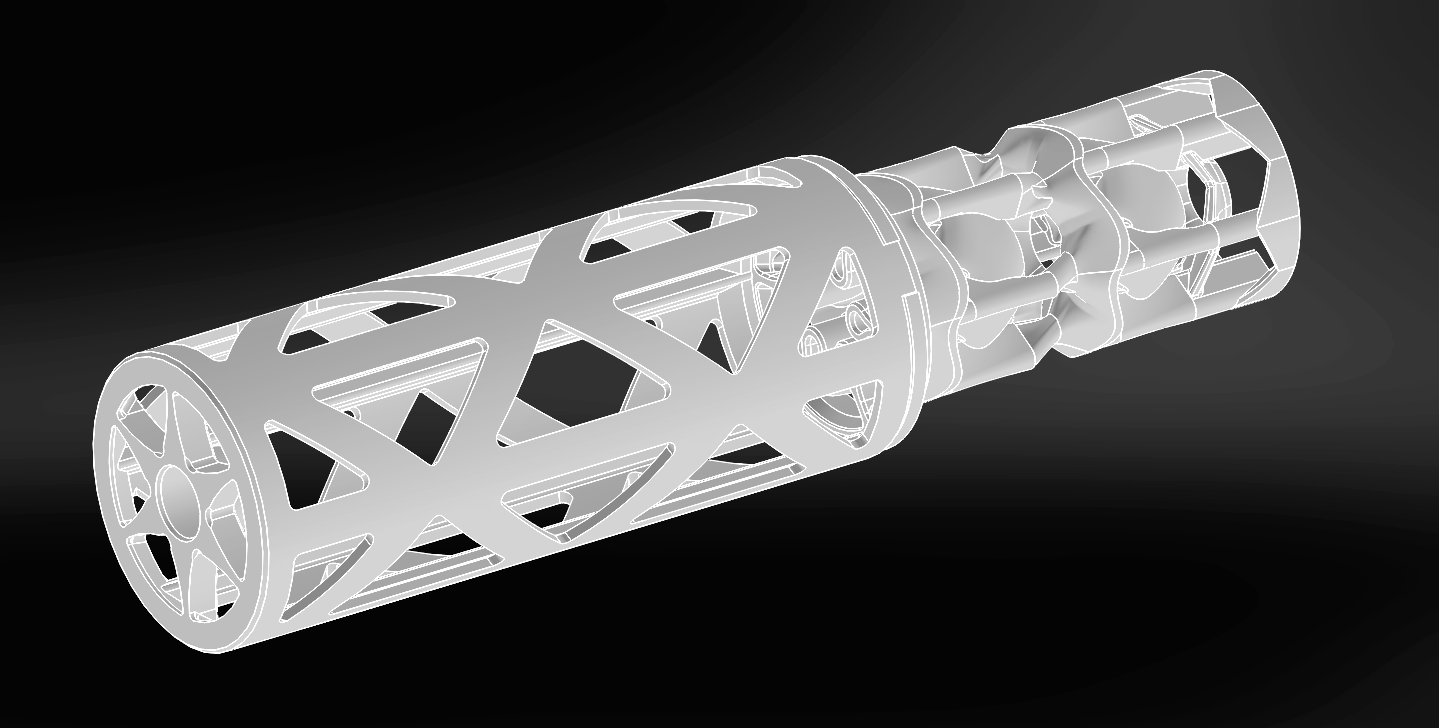

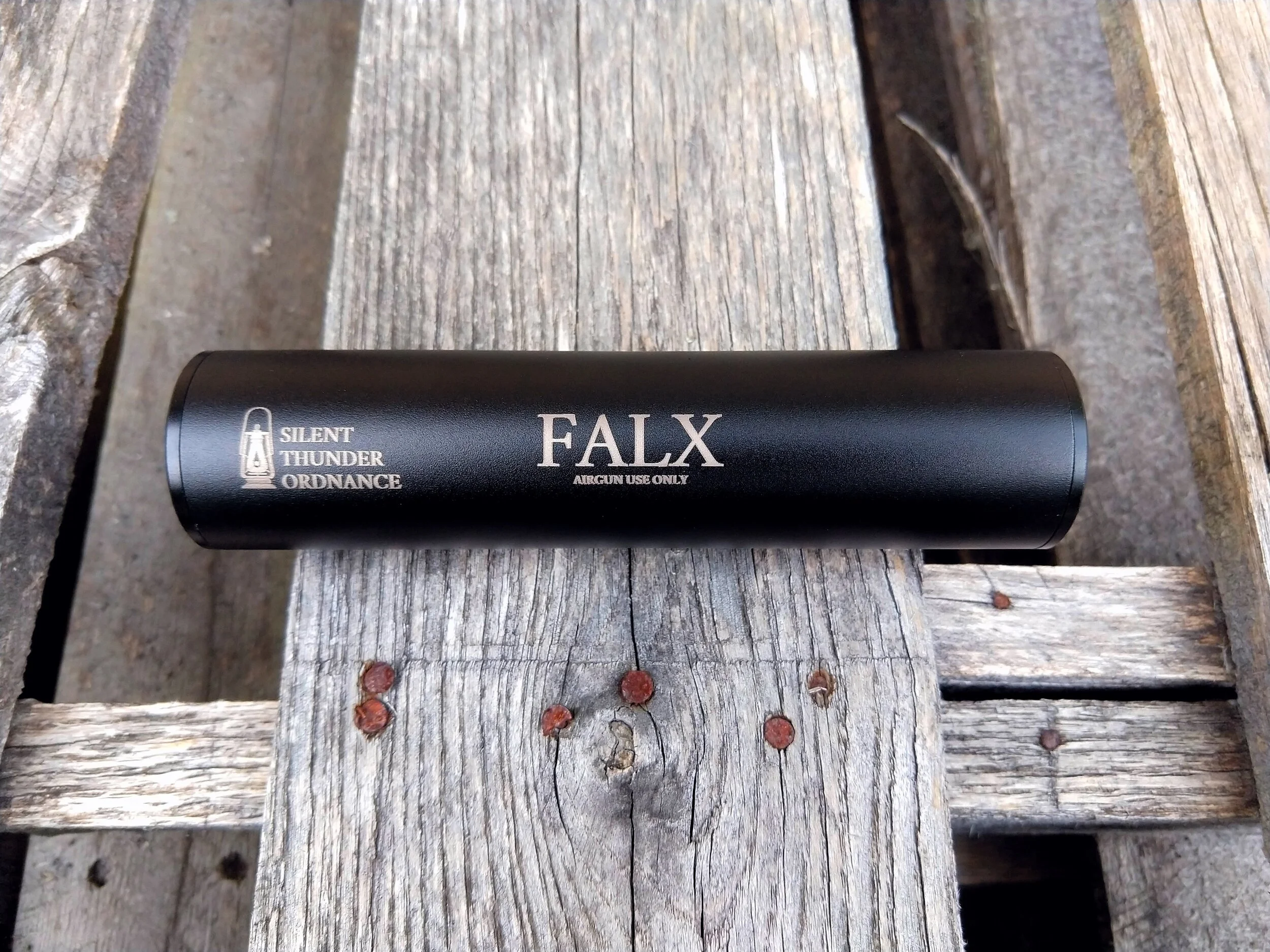

The second, more important, thing it means going forward though is a new moderator: the Falx. This design is intended to carry all my core principles of light weight, air stripping, flow delaying, and sound damping, which were developed in the carbon moderators, and carry them over to a semi-modular aluminum moderator in the Gladius footprint. This comes with a whole host of advantages. I’ve been working, for a year now and almost entirely unsuccessfully, on a modular moderator design. I sometimes get comments about how easy I make moderator development look. I understand how people get that impression from these blog posts, after all I usually blend a handful of interesting failures in with a few successes, but what you don’t see are often weeks or even months of experiments all of which end in failure and I have absolutely no idea why. Sometimes some thing just doesn’t work out and there is no clear reason. Even the Falx, which rides that line of too-large-tube-diameter, I’d been grinding away at totally unsuccessfully for months. And I don’t mean a little unsuccessfully, I mean producing peaks in the 150+ range on the .22 Crown level of this is hilariously not f*cking working, and having absolutely no idea why. Likewise I also don’t post my incremental tweaks and changes, where moving an aspect a mm or two in one direction or another creates a small gain. Point is there is a lot of grinding and a LOT of inexplicable failure which just doesn’t make for riveting reading. So too was it with truly modular airgun moderators, ones where sections could be taken separately and attached. In the end, it worked, but the results were bigger, heavier, more difficult to produce, and would have been more expensive. Why buy one moderator when you can buy four modular sections at four times the price? Yeah, didn’t make sense to me either. The Falx became my compromise, I call it modular but it is only really “semi-modular” in that the footprint remains the same but I am able to pull an entire core, or core section, out and replace it with another. The semantics of whether or not this counts I leave up to you, but you’ll see me refer to it both ways going forward. Sorry.

This modularity gives me a key advantage though when it comes to moderator development, and you all key benefits when it comes to their use. The out-going composite moderators used a monocore system, caps are held together by a core which is held in tension. This was an elegant solution, but limited space and design elements. Critically, it meant every time I wanted to test something, I had to build the entire moderator. With threaded end caps in an aluminum tube, the core no longer needs to be held in tension. This frees me to make multi-part cores which are modular, serviceable, replaceable, and upgradeable. I can now simply swap internal components in testing, allowing quicker and easier assessment of different design elements. Also things like true floating dampers, multi-axis chambers, and an even wider variety of materials are, not just possible, but utilized to make the Falx even quieter than its all-composite brethren. This is, simply put, the quietest moderator design I’ve ever built, and I’m not stopping here. As new revs. come out, users who want to upgrade will be able to send their units back and get the core swapped to the latest rev.

There is always a catch though, and this is true here as well. There is no getting around it, aluminum is heavier than composites. That said, I’ve done what I can to minimize it. Instead of increasing wall thickness and cost to allow machined designs on the outside of the tube, I opted for a thin smooth wall to maximize cross-sectional strength. For those looking for extra stylish flair, custom engraving is certainly a possibility. The result is a design which, while heavier than its all-composite counterparts at ~180 grams (varies by core), can still meet or beat the trend for mass-to-volume-ratio of other aluminum moderators on the market and absolutely monster it for mass-to-sound ratio.

So now, having gotten that sleazy sales pitch, how did I get here, and how does the Falx actually perform?

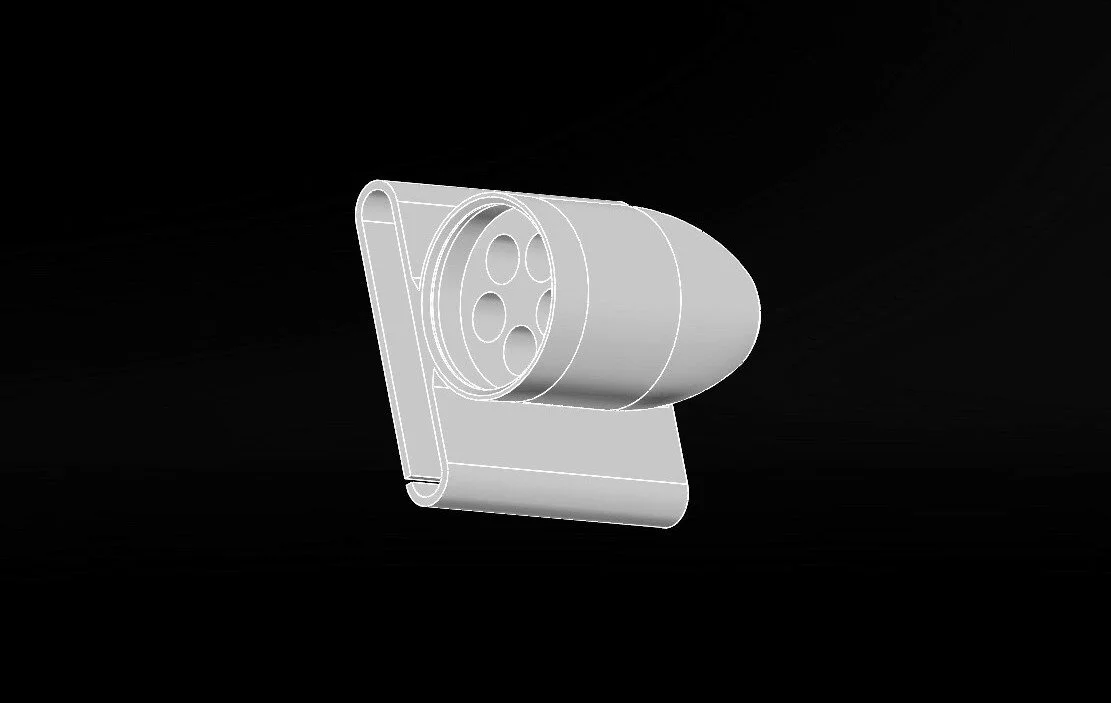

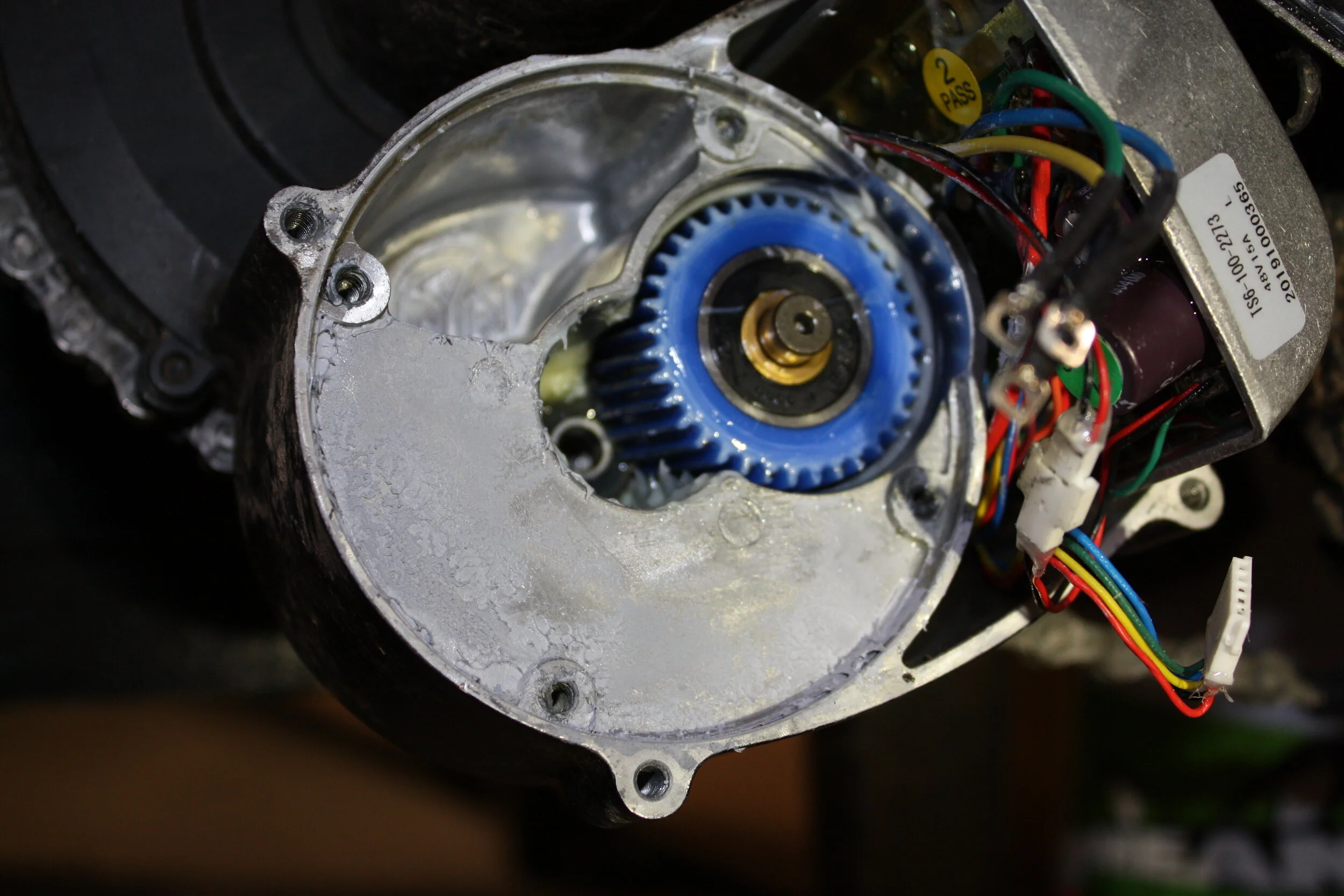

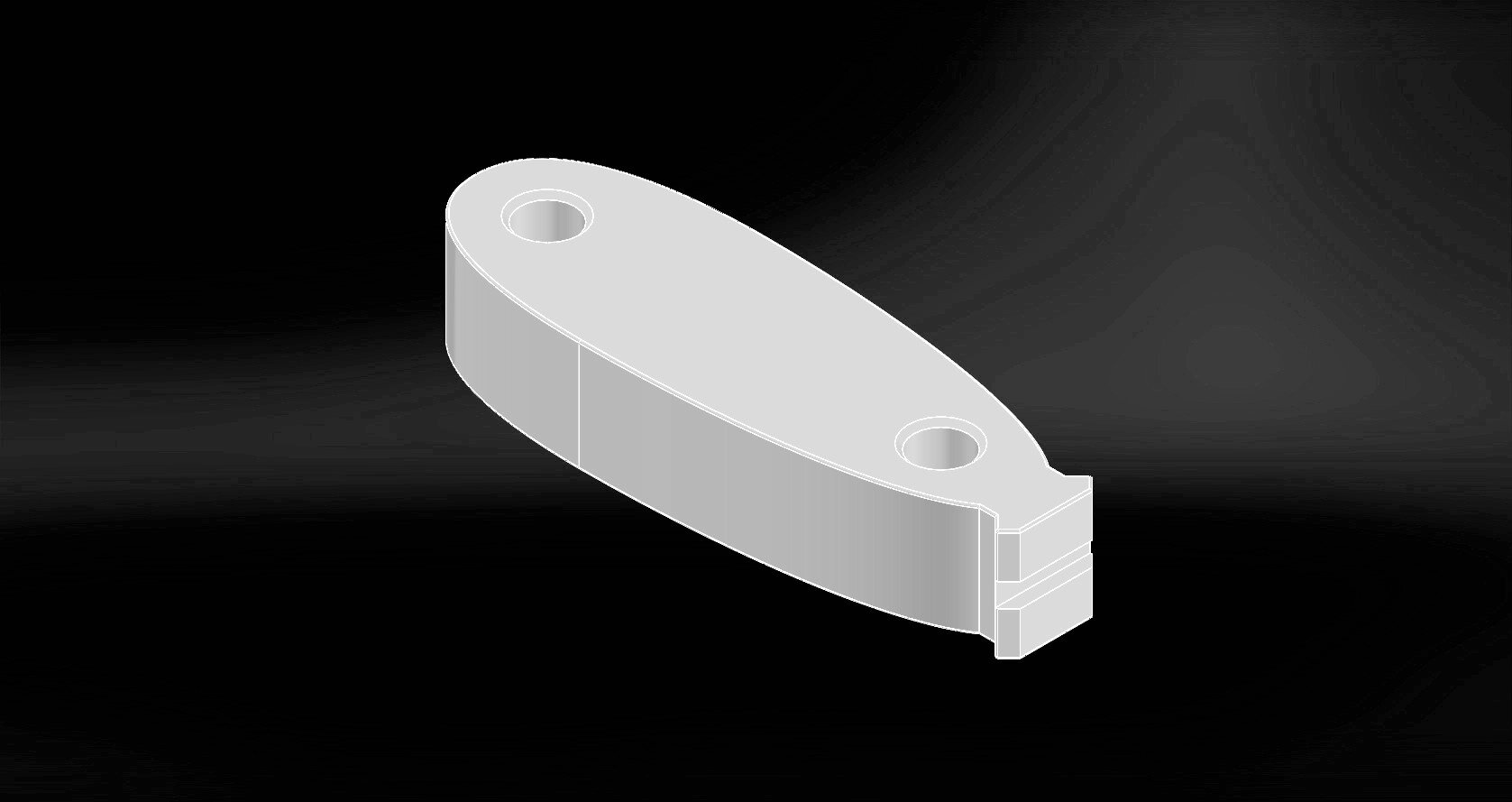

The lack of scalability of the carbon monocore designs was actually pretty clear pretty early on. So I started working on something I nickamed the Cerberus, named after the multi-headed-dog because it was meant to, not just solve the manufacturing problems, but sectioned and modular. Each module could be attached to another via what was initially taper mount via threads and what evolved into a taper-and-lug system to ensure concentricity was maintained. And this would mean, instead of being stuck with whatever performance/size envelopes I built something for, people could grab pieces to actually tune their moderators to their rifles. And this is a key thing I want to hover over, the idea that a moderator to perform optimally should be relatively tuned to the rifle. This isn’t so much the case with a typical “hair curlers and washer baffles” design as you’re essentially asking a question of size/weight vs. sound attenuation as sections are all identical, these gas diode moderators have measurably better performance on a rifle for which they’re optimized. So that is great, where the heck is it? Well as it turns out, in solving the old manufacturing problems I created a whole suite of new ones. After all who wants to buy one moderator when you can buy one in 5 parts for five times the price? I beavered away on this for ages before giving up. I think I’ve said this before, but for every test you see here there are dozens of failures that either aren’t interesting or I haven’t the foggiest idea why they didn’t work. And nobody wants to read that any more than I want to take the time to write it all up. Never the less, I think some of these designs are cool so for your perusal I post just a handful of them here.